Kraft paper is use for a variety of everyday tasks such as packaging items, arts and crafts and even cleaning. It’s also the usual choice of paper for creating paper bags. Whilst you may be use to using kraft paper at home and in the workplace, you may not know much more about it, such as how it’s make and whether or not it’s recyclable. If so then you’re in the right place. In this article we will learn more about kraft paper and its manufacturing process.

What is kraft paper?

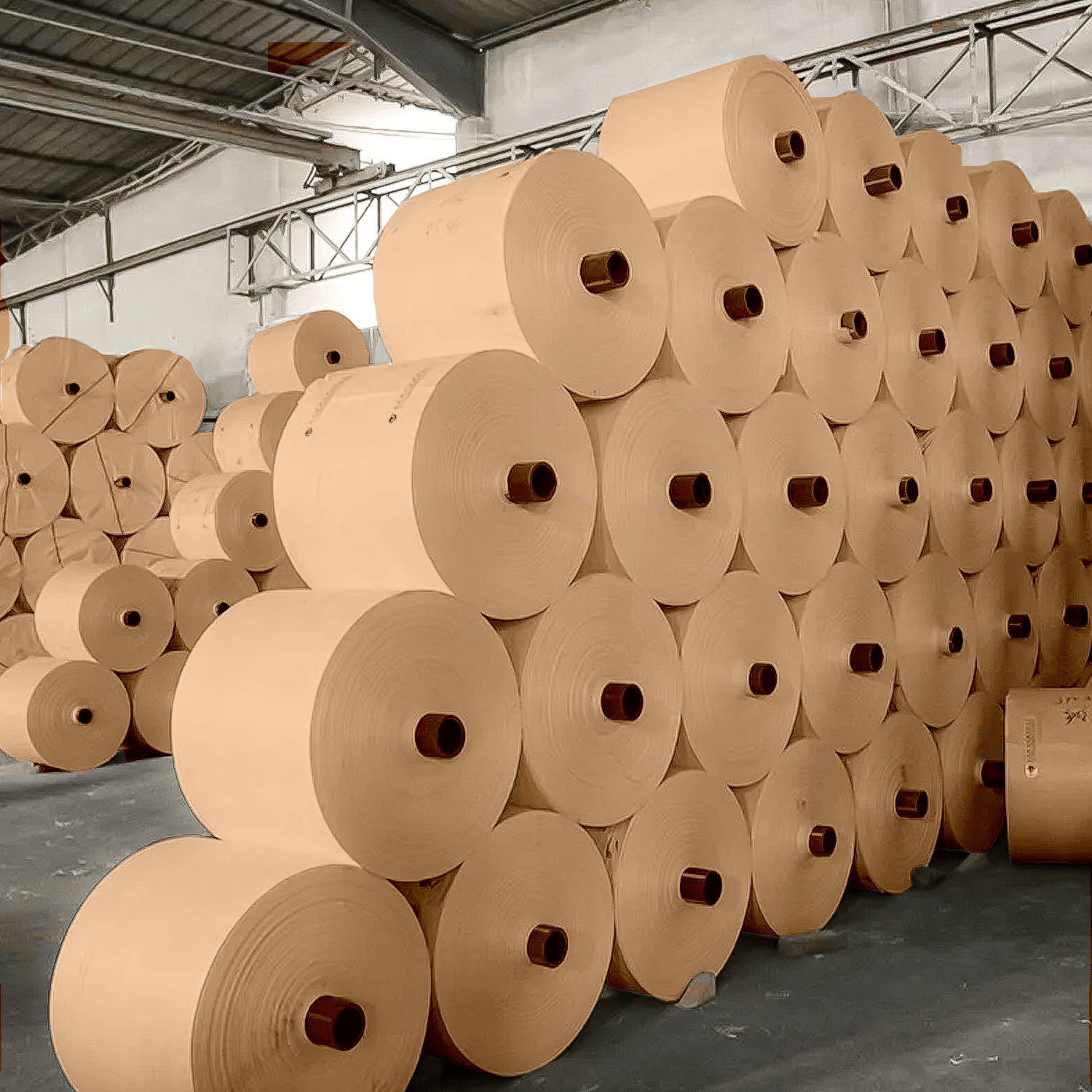

It is a type of brown paper that’s typically make from wood chips. For over a century it has been use for everything from packaging to printing. It usually comes in large rolls that can then be cut and shape for the desire use. Even though kraft isn’t waterproof, it’s strong enough to provide a waterproof barrier if treat properly. The most common way to treat kraft is by coating it with wax or oil. This allows the kraft to stand up against moisture, making it perfect for food packaging, one of the most popular uses for kraft (more on those later).

What is kraft paper used for?

It is use in a variety of everyday ways. From packaging to printing, kraft paper is an economical choice that is long-lasting. Due to its heavy-duty and tear resistant properties, It is often use when a thicker alternative to traditional paper is require. As it hasn’t been bleach extensively, It tends to be more sturdy and long-lasting than white or colour paper alternatives. It is one of those everyday items that we easily take for grant, we’re always using it but rarely stop to appreciate how useful it can be.

Often use to wrap fragile items or as packaging for groceries, gifts and shopping, we probably overlook kraft when in fact, we would be lost without it. It has become a popular choice for gift wrap and stationery in recent years, thanks in part to its environmentally friendly nature as well as the “pinterest-worthy” rustic aesthetic it creates.

Some common uses for kraft paper include:

- Food wrapping

- Arts and crafts

- Packaging and protecting fragile items

- Gift wrap

- Clothing tags

- Surface protection

How is kraft paper made?

It is make using the chemical process of converting wood into wood pulp. The term “kraft” refers to this process where softwood chips are cook using intense pressure and heat in a mixture of strong alkaline chemicals. The two structural components of wood are lignin and cellulose. When it comes to making kraft paper, it’s the cellulose we need so this needs to be separate from the lignin.

A good way to think about making kraft is comparing it to cooking instant noodles. When you first take them out of the packet the noodles are hard and tightly compact together, much like the wood chips. Add hot water to them however and the noodles become soft and separate, this also happens to the properties of the wood chips allowing manufacturers to separate the useful components from the parts that aren’t need to make kraft paper. The pulp is then wash and screen through large rollers to remove any large chunks and the large rolls of kraft paper that we are use to seeing in factories and manufacturing plants are create.

Is Brown Kraft Paper Recyclable?

Brown paper is still widely use in 2022 because it can be recycle endlessly. Using paper bags instead of plastic ones is just one example of how our collective environmental consciousness leads us to adopt more sustainable practices. Although kraft paper starts as wood, it may be recycle into the new report by breaking it down into tiny enough bits to be transform into pulp. Today, most kraft paper rolls are create from recycle and raw resources. Recycling paper is quite similar to the original kraft manufacturing process, albeit one that uses fewer chemicals and is gentler on the environment.

How thick is kraft paper?

When it comes to weighing out the thickness and weight of kraft we usually use the metric GSM (Grams per Square Metre). Put simply, the higher the GSM the thicker the roll of paper. This metric allows manufacturers and buyers to know exactly what the quality of the paper is like. Different uses for kraft require different weights. It is available in various weights but is generally one of the thicker papers options on the market making it a durable choice for packaging and paper bag manufacturing.